Driving in and out with forklifts

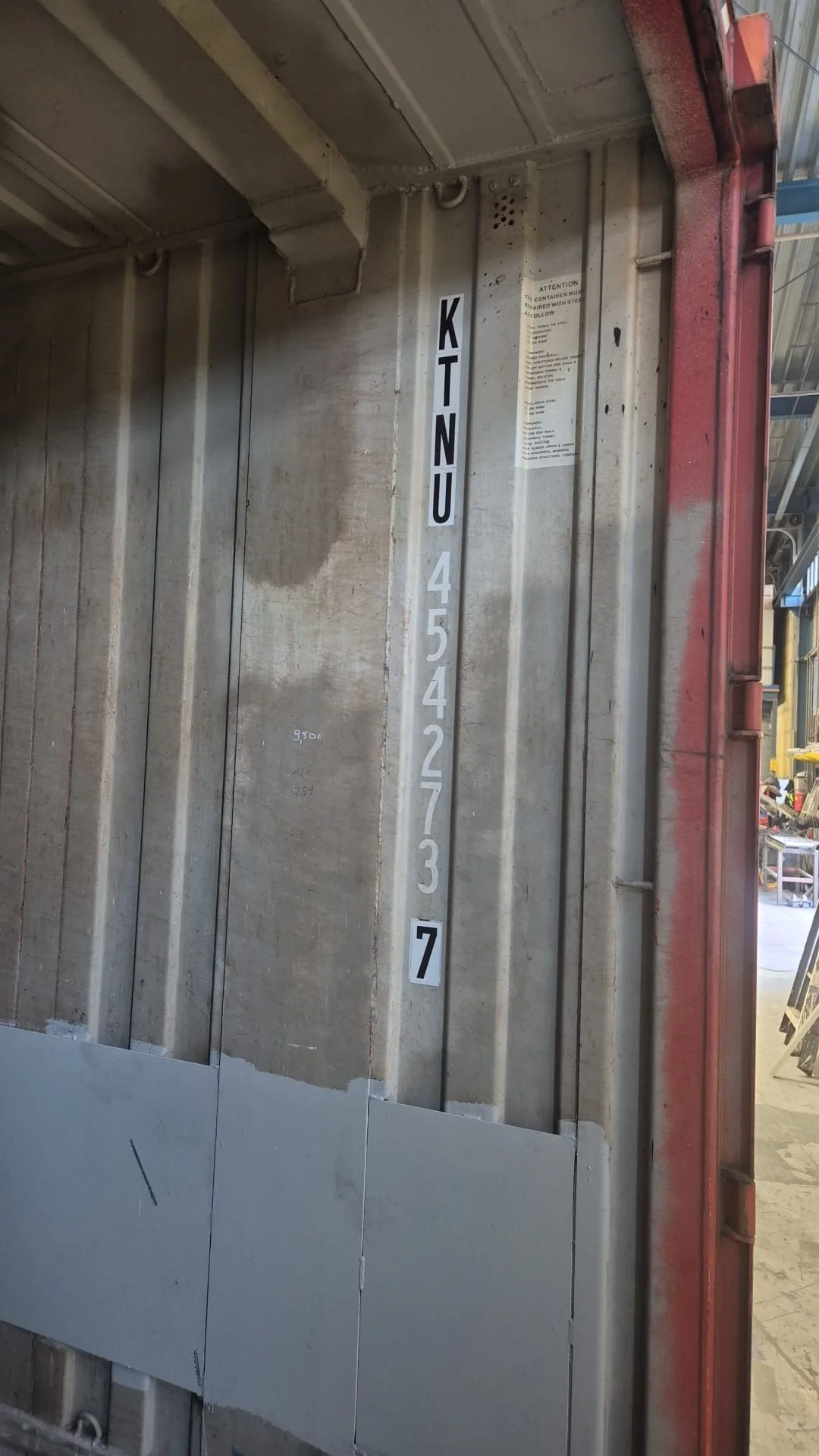

For customers who **use their 45’PWHC containers intensively**, such as frequently driving forklifts in and out and loading and unloading pallets, K-tainer offers an **impact-resistant modification**. Our solution extends the lifespan of the container and reduces maintenance costs.

Specifications per container:

- 5 mm thick chequered plate floor up to the gooseneck for maximum durability

- Reinforced walls: left and right 10 plates of 3 mm thickness and 62.5 cm high, welded at 30–40 cm from the floor

- Lower section of the first two meters fitted with PIR insulation and bitumen for extra protection

Benefits of Modification

- Impact-resistant floor and walls for intensive use

- Less maintenance and easier repairs

- Durable and suitable for daily loading and unloading

New or Used

K-tainer can apply these impact-resistant modifications to **existing containers**, or deliver **new or well-used 45’PWHC containers**, fully customized to your requirements.

Repair of Reefer Containers

K-tainer provides **professional repair of reefer containers**, ensuring your cooled cargo stays safe at all times. Our specialists handle refrigeration units, insulation, doors, and electrical systems to keep your containers performing optimally.